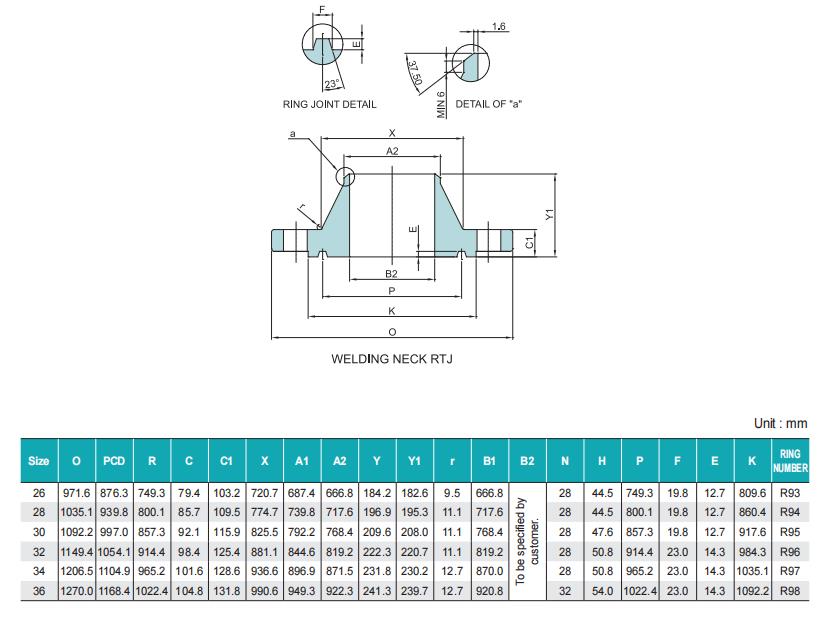

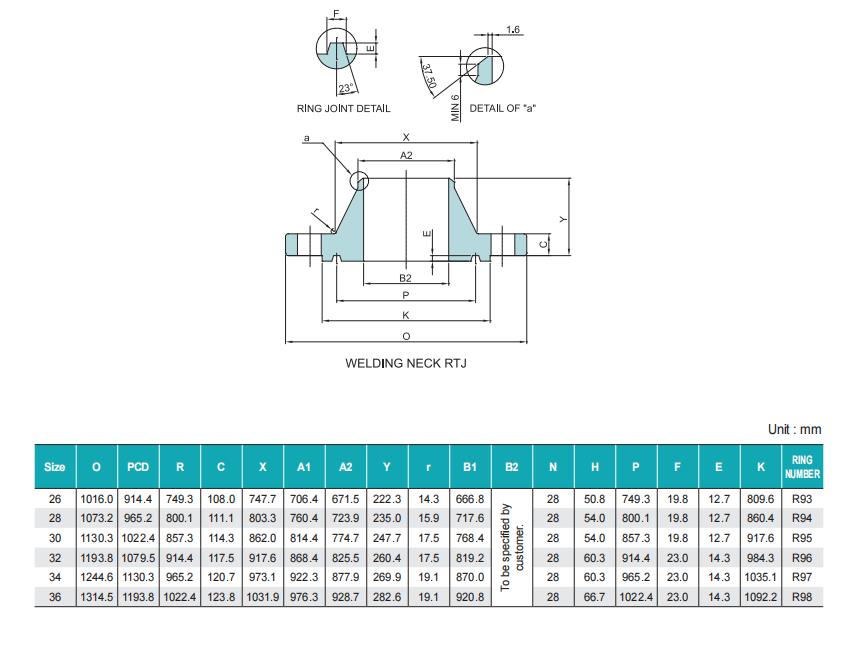

Carbon Stainless Steel Welding Neck Wn Flange Rtj Class900 600 300

Product Data

Product Introduction

Common RTJ welding neck flange models include WN, SO, BL, LJ, TH, etc., with a pressure rating of typically 150 # -900#, suitable for pipeline systems in various fields such as petrochemical, fertilizer, papermaking, pharmaceuticals, food, etc.

Welding Neck RTJ flange refers to a type of welding neck flange connection method with a boss and circular groove. BS3293 is a standard specification used for the design and manufacturing of steel butt welded flanges. RTJ is the abbreviation for Ring Type Joint, which means ring gasket seal.

The Welding Neck RTJ flange usually consists of three parts: the flange itself, flange washer (RTJ washer), and fasteners such as bolts and nuts. This type of flange connection method uses butt welding to connect the flange to the pipeline, and uses RTJ gaskets to form a seal between the flange and the flange, thereby preventing fluid leakage.

Size

The size of RTJ with welding neck flange is usually determined by the diameter and wall thickness of the connected pipeline or equipment. For example, in the ANSI B16.5 standard, the size range of RTJ flanges is from 1/2 inch to 36 inch, and the thickness range of connecting pipes is from SCH 10 to SCH 160.

Pressure level

The pressure rating of RTJ flanges is usually determined by their material and size. In the ANSI B16.5 standard, the pressure rating of RTJ flanges ranges from 150 pounds to 900 pounds, and other standards also have similar pressure rating options.

Application scope

The application methods of RTJ welding neck flanges include connecting two pipelines or equipment, connecting valves and pipelines, connecting pipelines and pumps, etc. Its sealing performance is good, and different materials can be used to meet the requirements of different media. It has characteristics such as high temperature resistance, corrosion resistance, and impact resistance, and is widely used in various industrial projects.

Advantage

1. Able to withstand working requirements in high-pressure and high-temperature environments

2. High tightness and less prone to leakage

3. The annular sealing surface can be reused

Disadvantages

1. Special metal ring gaskets are required,

2. It is necessary to strictly control factors such as pre tightening force

3. Both installation and maintenance require professional personnel to operate.

Therefore, BS3293 welded neck flange RTJ is suitable for pipeline systems that require harsh conditions such as high pressure, high temperature, strong acid and alkali, and reliable sealing measures need to be adopted to ensure operational safety and environmental protection requirements.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top