Carbon Steel Seamless Butt Weld Pipe Fittings Elbow 45 Degree

Picture Presentation

Product Presentation

In a piping system, an elbow is a fitting that changes the direction of a run. A kind of connecting pipe fitting commonly used in pipeline installation, connecting two pipes with the same or different nominal diameters to make the pipeline turn at a certain angle, and the nominal pressure is 1-1.6Mpa.

The common angles are 45 ° and 90 ° 180 °. In addition, there are 60 ° and other abnormal angle elbows required by the project.

The materials of elbows include cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, nonferrous metals and plastics.

The common connection methods with pipes include direct welding, flange connection, hot melt connection, electric melt connection, threaded connection and socket connection.

Carbon steel elbow is used for connecting pipe bends, connecting two pipes of the same nominal diameter, so that the pipe is angular bent. The material is divided into carbon steel elbow, cast steel elbow, alloy steel elbow, stainless steel elbow, copper elbow, aluminum alloy elbow, etc. Elbow can be said to cover the use of all walks of life across the country, small to the family to the enterprise. Each carbon steel elbow has its own advantages and uses, warmly welcome new and old friends to come to buy. Carbon steel elbow is a common connection in pipeline installation, used for the connection of pipe bend, carbon steel elbow can get a shortage in the market and continue to replace some traditional anti-wear materials, the fundamental reason is its excellent product quality, as well as in the traditional anti-wear materials.

Advantages of carbon steel elbow

(1) Carbon steel elbow is suitable for pipeline system of petroleum, natural gas, chemical industry, hydropower, construction and boiler industries

(2) The bad material is flat or developable surface, so the blanking is simple, the precision is easy to ensure, and the assembly and welding is convenient

(3) Due to the above two reasons, the manufacturing cycle can be shortened and the production cost is greatly reduced. Since no special equipment is required, it is especially suitable for on-site processing of large carbon steel elbows

(4) There is no need to break the pipe as raw material, can save the cost of pipe making equipment and mold, and can get any large diameter and wall thickness

Relatively thin carbon steel elbow, carbon steel elbow can get a shortage in the market and continue to replace some traditional anti-wear materials, the fundamental reason is that its excellent product quality, and compared with the traditional anti-wear materials, such as cast stone, cast steel and centrifugal flow ceramic materials have many advantages, carbon steel elbow lined with 95 ceramics, Alumina content is not less than 95%, and all the high temperature phase A-AL203, sintering temperature up to 1670C, to ensure the quality of the material, from the actual effect of anti-wear, carbon steel elbow durable time is more than 5 times the composite ceramic elbow.

Pressure Rating

Sch5s、Sch10s、Sch10、Sch20、Sch30、Sch40s、STD、Sch40、Sch60、Sch80s、XS; Sch80、SCH100、Sch120、Sch140、Sch160、XXS;

The most commonly used are STD and XS.

| Elbow | |||||||||

| Type | (Long radius/Short radius)15degree, 30 degree, 45 degree,90 degree, 180 degree | ||||||||

| Technics | Seamless Elbow, Butt Welded Elbow | ||||||||

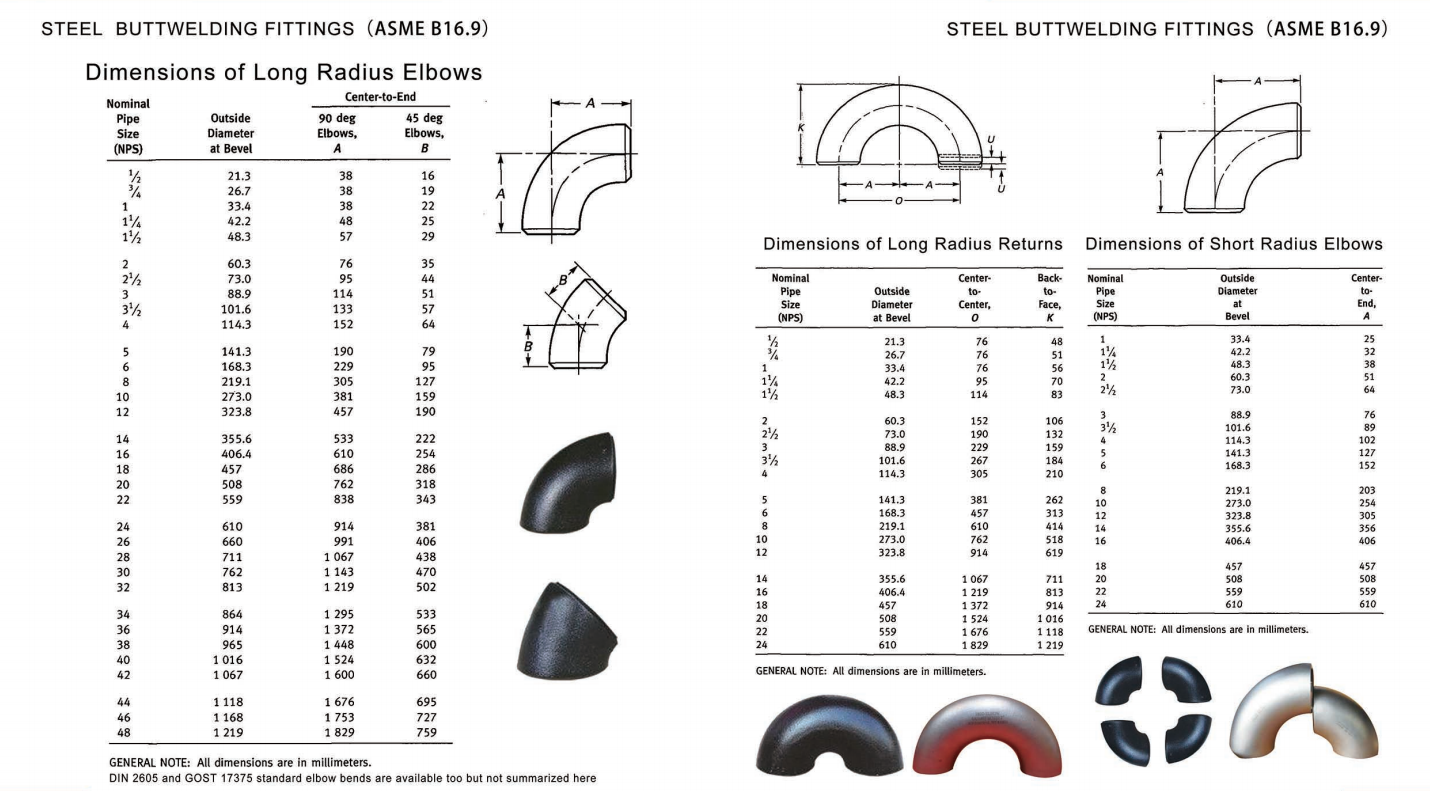

| Size | 1/2"-48"(DN15-DN1200) | ||||||||

| Varieties | SCH5,SCH10,SCH20,SCH30,STD, SCH40, SCH60, XS, SCH80, XXS,SCH100,SCH120,SCH140,SCH160 |

||||||||

| Standard | ANSI B 16.9/ANSI B16.28/MSS SP43/MSS P75/JIS2311/JIS 2312/JIS2313/ DIN2615 /GB-12459/GB-T13401,GOST17375 | ||||||||

| Material | Carbon steel: ASTM A234 GR WPB , ST37.2 , ST35.8... Stainless steel: A403 WP304/TP304 , WP304L/TP304L , WP316/TP316 ,WP316L/TP316L, WP321/TP321 , WP310/TP310….. |

||||||||

| Surface treatment | Carbon steel:Shot blasted, black painting, rust-proof oil, galvanizing,, hot galvanizingtransparent oil, Alloy steel:Shot blasted, black painting, rust-proof oil,transparent oil, galvanizing, hot galvanizing Stainless steel: pickled,Polish |

||||||||

| Application Fields | Chemical Industry /Petroleum Industry /Power Industry/Metallurgical Industry/Building Industry/Ship-building Industry | ||||||||

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top