A na-eji flange nrụgide dị elu jikọọ ọkpọkọ ma ọ bụ akụrụngwa nwere nrụgide dị elu karịa 10MPa.Ka ọ dị ugbu a, ọ na-agụnyekarị flange elu-nrụgide ọdịnala yana nrụgide onwe onye na-agbatị flange.

Omenala High Pressure Flange

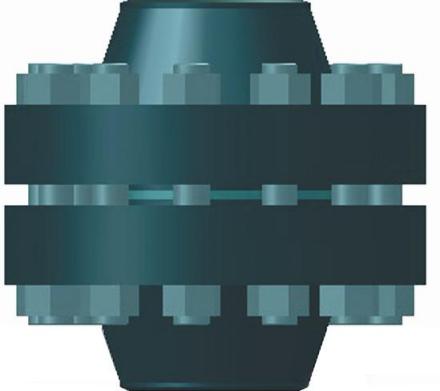

Nchịkọta nke Flange High Pressure Traditional High Pressure

The omenala elu-nrụgide flange bụ akụkụ na-eji plastic deformation nke sealing gasket (oval gasket, octagonal gasket, oghere gasket, wdg) iji nweta akara mmetụta.Ejikọtara ya na njedebe ọkpọkọ iji mee ka ọkpọkọ na ọkpọkọ jikọọ ibe ha.Enwere oghere na flange ahụ, a na-ejikọta flange abụọ ahụ site na bolts stud.

Omenala elu-nrụgide flange bụ n'ozuzu mejupụtara a ụzọ flanges, a gasket na ọtụtụ bolts na akụ.A na-etinye gasket mkpuchi ahụ n'etiti ebe mkpuchi nke flanges abụọ.Mgbe emechara nut ahụ, nrụgide a kapịrị ọnụ na mkpuchi mkpuchi gasket na-erute uru ụfọdụ, nke ga-eme ka nrụrụ plastik mee ka njikọ ahụ sie ike.Enwere ike iji ụdị a maka ọkụ ọkụ, ihe mgbawa, mgbasa ozi na-egbu egbu na oge nrụgide dị elu, mana ntụkwasị obi akara adịghị mma.

( Eserese njikọ flange nrụgide dị elu-Welding olu Flange)

Ndị ọzọ:Gaa na Flange,Wepụ na Flange Plate

Njirimara nke Flange Mgbakasị Ọdịnala

1. Ụkpụrụ akara bụ nke nrụrụ plastik

2. Njikọ njikọ

3. Bolts ga-ebu esemokwu, nrụgide dị iche iche okpomọkụ, oge na-ehulata, torque na nrụgide mpụga ndị ọzọ

4. Ọ dị oke ibu ma dị arọ, ọ na-esikwa ike ịwụnye na ọnọdụ.

5. Arụ ọrụ mkpuchi na-akwụghị ụgwọ, karịsịa n'ọnọdụ siri ike (oke okpomọkụ, nrụgide dị elu, na usoro na-egbu egbu), na-adịkarị mfe na-agbapụta, na-akpata nnukwu nsonaazụ.

Njirimara ngwa nke Flange Nrụgide Dị Elu:

A na-ejikarị flange nrụgide dị elu na ntinye pipeline.Njikọ flange nrụgide dị elu bụ ụzọ njikọ dị mkpa maka ịrụ ọrụ pipeline.Ọ na-ejikọkarị njikọ dị n'etiti ọkpọkọ, na-arụ ọrụ dị mkpa na uru.Njikọ flange dị elu bụ idozi ọkpọkọ abụọ, ọkpọkọ ọkpọkọ ma ọ bụ akụrụngwa na efere flange n'otu n'otu, gbakwunye gaskets flange n'etiti flanges abụọ ahụ, ma jikọta ya na bolts iji mezue njikọ ahụ.Ụfọdụ ọkpọkọ na akụrụngwa nwere flange nke ha, nke bụkwa nke njikọ flange.

Arụmọrụ nke Flange Mgbagide Dị Elu:

1. Yiri eguzogide: ọdịnaya nke Al2O3 na seramiiki oyi akwa nke seramiiki lined mejupụtara ọkpọkọ ígwè dị ukwuu karịa 95%, na micro hardness bụ HV1000-1500, n'ihi ya, ọ nwere oké elu eyi nguzogide.Nguzogide iyi ya karịrị okpukpu iri dị elu karịa nke carbon steel a na-emenyụ emenyụ, ma dị mma karịa nke tungsten carbide.

2. Corrosion eguzogide ceramics bụ ndị na-anọpụ iche ihe na anụ chemical Njirimara, magburu onwe corrosion eguzogide na acid-eguzogide, na ike iguzogide dị iche iche inorganic acid, organic acids, organic solvents, wdg Ya corrosion eguzogide bụ ihe karịrị ugboro iri nke igwe anaghị agba nchara.

Ụdị nrụgide onwe onye dị elu

Mwebata ngwaahịa nke ụdị nrụgide onwe onye dị elu:

Nrụgide dị elu nke na-ejide onwe ya bụ ụdị ọhụrụ nke flange nrụgide dị elu, nke na-eme ka njikọ pipeline dị n'okpuru ọnọdụ ọrụ siri ike dị ka nrụgide dị elu, okpomọkụ dị elu na nnukwu corrosion.Flange omenala na-adabere na nrụrụ plastik nke gasket iji nweta ọrụ akara, nke bụ nke akara dị nro.Isi ihe na-eme ka ọ dị elu nke na-eme ka ọ dị elu nke onwe ya bụ akara ọhụrụ pụrụ iche, nke bụ akara siri ike nke e mepụtara site na nrụrụ na-agbanwe nke egbugbere ọnụ akara (T-arm) nke mgbanaka akara.

Nrụpụta nke ụdị nrụgide onwe onye dị elu:

Ihe mejupụtara ferrule, oghere, mgbanaka akara na bolt.

1. Mgbanaka akara nke metal: mgbanaka akara bụ akụkụ bụ isi nke nrụgide onwe onye na-agbatị flange, na akụkụ obe ya yiri ụdị "T".Mgbe emechara flange ahụ, a na-ejikọta rebar nke mgbanaka akara site na njedebe nke ihu abụọ nke nkwonkwo HUB ma mepụta otu ihe na nkụnye eji isi mee, nke na-eme ka ike nke akụkụ njikọ dịkwuo mma;Ogwe aka abụọ nke ngalaba "T", ya bụ egbugbere ọnụ akara, na cone dị n'ime nke nkwonkwo aka na-emepụta ebe a na-emechi ihe, nke na-agbatị kpamkpam n'okpuru ike mpụga (n'ime oke mkpụrụ) iji mepụta akara.

2. Socket: mgbe oghere abụọ HUB na-ejikọta ya site na ferrule, a na-agbanye ha na ọgịrịga nke mgbanaka akara, na egbugbere ọnụ na-ekpuchi ya na-esi n'ime ime mkpuchi nke oghere ahụ, nke na-eweghachite ibu nke elu mkpuchi ahụ. nke oghere azụ na egbugbere ọnụ nke mgbanaka akara, na-akpụ a onwe mesiri ike na-agbanwe akara.

3. Ferrule: ferrule nwere ike gbanwee kpamkpam na ntụziaka 360 Celsius maka ntinye dị mfe.

4. Anọ tent nke spherical bolts: n'ozuzu, naanị anọ tent nke tangential elu-nrụgide spherical bolts na-chọrọ maka onye ọ bụla set nke elu-nrụgide onwe tightening flange mezue mkpokọta guzosie ike.

Njirimara ngwaahịa nke ụdị nrụgide onwe onye dị elu:

1. Akara usoro: isi nke elu-nrụgide onwe tightening flange bụ a pụrụ iche metal ka metal ọhụrụ akara, ya bụ, akara na-kpụrụ site na-agbanwe deformation nke sealing egbugbere ọnụ (T-ogwe) nke akara mgbanaka, nke bụ nke akara. ka akara siri ike;Nchikota nke aka uwe, ferrule na akara mgbanaka na-eji na-emepụta ahụ siri ike siri ike, nke na-eme ka ike nke njikọ akụkụ dị nnọọ ukwuu karịa ike nke ọkpọkọ isi metal n'onwe ya.Mgbe a na-agbanye ya, ọgịrịga na egbugbere ọnụ na-arụ ọrụ nke ike na nkedo n'otu n'otu, nke nwere ike ọ bụghị nanị na-eme ka akara ahụ sie ike, kamakwa na-ewusi pipeline ahụ ike, na-eme ka ike zuru ezu nke akụkụ njikọ ahụ dịkwuo elu.

2. Tensile onwunwe: N'ọtụtụ ọnọdụ, elu-nrụgide onwe tightening flange na njikọ nwere ike iburu tensile ibu mma karịa ọkpọkọ n'onwe ya;Nnwale ndị na-emebi emebi gosiri na flange ahụ ka na-adịchaghị mma na-agbapụtaghị mgbe pipeline dara n'okpuru ibu nkwụ.

3. Nguzogide na-ehulata: ọnụ ọgụgụ dị ukwuu nke ule na-egosi na flange agaghị agbapụta ma ọ bụ na-atọhapụ mgbe ọ na-ebu ibu na-ehulata.Nnwale n'ezie: DN15 dị elu nrụgide onwe tightening flange na-welded na ọkpọkọ ma doro ọtụtụ oyi ekwe.Njikọ nke elu mgbali onwe tightening flange agaghị ihichapụ na bolts agaghị adị rụrụ.

4. Compressibility: na nkịtị pipeline ngwa, elu-nrụgide onwe tightening flanges agaghị ebu ibu mkpakọ;Mgbe ibu mkpakọ dị elu na-eme, a na-ekpebi oke kachasị elu nke na-eme ka ọ dị elu na-eme ka ọ dị elu nke na-eme ka ọ dị elu site na ike kachasị nke ọkpọkọ.

5. Mmetụta mmetụta: obere na obere geometric size, nke nwere ike iguzogide mmetụta mmetụta nke omenala elu-nrụgide flange enweghị ike iburu;Ngwongwo pụrụ iche na nhazi mkpuchi ọla na-eme ka nguzogide mmetụta ya dịkwuo elu.

Nguzogide corrosion: nguzogide corrosion nke ihe dị iche iche nwere ike izute ihe nchebe corrosion pụrụ iche nke gburugburu ebe eji eme ihe.

Oge nzipu: Dec-06-2022