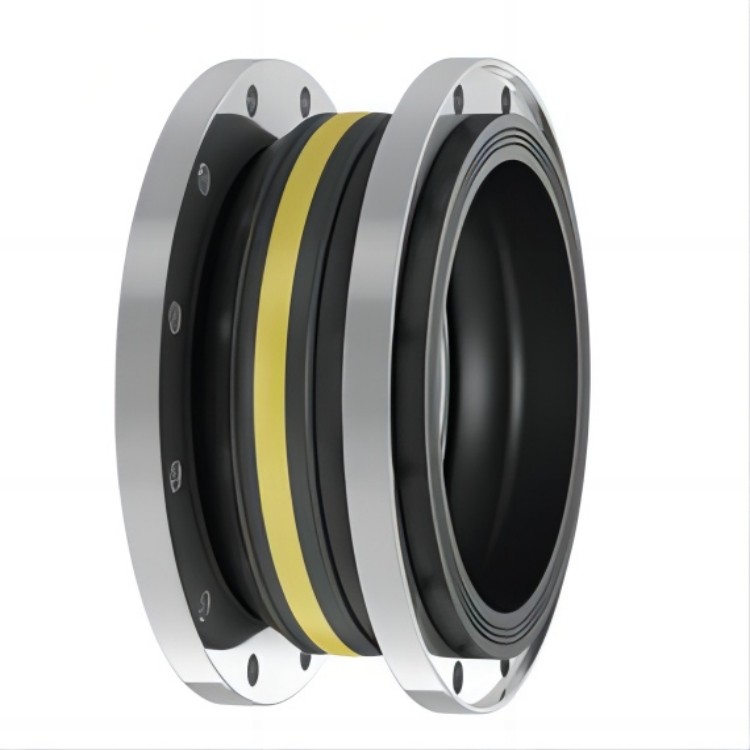

Single Ball Clamp Flexible Rubber Expansion Joint DN25-DN1200

Product Data

| Product Name | Clamp Flexible Rubber Expansion Joint | |||||||

| nominal diameter | DN25-DN1200 | |||||||

| total lenght | 150mm-200mm | |||||||

| Product material: | natural rubber, acid and alkali resistant, nitrile, etc | |||||||

| Applicable medium: | water, gas, particles, etc | |||||||

| Connection mode: | clamp connection | |||||||

| Applicable Temperature | 10°C-150°C | |||||||

| Scope of application: | connection with pump, valve, fire equipment, large vibration, hot and cold change frequently pipeline. | |||||||

Product Introduction

The clamp type flexible rubber joint is mainly sealed by a rubber sealing ring, which is also made by high-temperature vulcanization, with good elasticity, acid alkali resistance, and corrosion resistance

The sealing ring of the clamp type flexible rubber joint can be divided into two types: circular and conical, and the judgment method is determined by the caliber size. The common form is the single ball rubber expansion joint

The clamp type flexible rubber soft joint mainly utilizes the unique properties of rubber, such as high elasticity, high airtightness, medium resistance, and radiation resistance. It is made of high-strength, cold and hot stable polyester cord fabric that is diagonally mixed with it, and is cross-linked through high-pressure and high-temperature molding. The internal density is high, and it can withstand high pressure. The elastic deformation effect is excellent. The product structure is designed with a high end face arc, long curve, and multiple displacement functions, Especially used in places with complex geological conditions, large settlement amplitude, and frequent changes in cold and hot temperatures during pipeline operation, which can easily cause pipeline damage. Utilizing the elastic sliding displacement of rubber and the heat transfer and dissipation function of deformation mechanical force, it effectively eliminates the physical damage caused by displacement of pumps, valves, and pipelines themselves.

Installation:

When installing the clamp flexible rubber joint pipeline, first stretch the clamp type flexible rubber joint to the required length, then tighten the limit bolt, and then tighten the diagonal screw. This limit device is the core of the clamp type flexible telescopic joint, which can effectively solve the problem of pipeline expansion displacement.

Characteristic:

1. Reasonable structure with high stress intensity

The working state of the clamp is equivalent to a pressure vessel, and the axial force of the medium is completely borne by the clamp, while the bolt only bears the radial force of the clamp. Due to the limited width of the sealing ring, the radial force is much smaller than the axial force. When connecting flanges, the bolts bear all axial forces and the compression force of the gasket.

2. Good self sealing effect

The sealing effect depends on the pressure of the medium in the pipeline on the rubber ring. The greater the pressure, the better the sealing performance. To prevent medium leakage without pressure, the inner diameter of the rubber ring should be smaller than the outer diameter of the pipe end interface. The rubber ring has a pre tightening force on the end pipe interface, which can prevent medium leakage when there is no pressure. Compared to flanges, the larger the pipe diameter, the higher the pressure, and the more prominent the advantage.

3. The pipeline connection is in a flexible state

There is a gap between the fixture and the pipe end, and the pipe can move slightly in the fixture. Therefore, a certain rotation angle is allowed between the two adjacent end pipes. After connecting the steel pipes, there is a gap between the pipe ends of the two steel pipes, allowing the pipes to move axially and adapt to the expansion and contraction of the pipes; Rubber ring connection between pipelines effectively reduces mechanical vibration by over 70%. Installation method of clamp type flexible expansion joint/clamp type expansion joint:

When the pipeline needs to be flipped, only a few bolts of the joint need to be removed to achieve any angle of flipping, without the need for cutting and welding, saving a lot of auxiliary work and costs, reducing labor intensity, and shortening the construction period. Compared to flange connections, it improves work efficiency by 6-8 times and requires less maintenance work

In summary, the clamp type rubber flexible joint as pipe expansion joint can provide good protection for equipment such as pipelines and valves. After use, it can also serve as a connection to the overall system, allowing equipment and pipelines to operate normally.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top