Stainless Steel Welded Elbow Seamless 45 Degree ANSI ASME B16.9

Picture Presentation

Product Presentation

In a piping system, an elbow is a fitting that changes the direction of a run. A kind of connecting pipe fitting commonly used in pipeline installation, connecting two pipes with the same or different nominal diameters to make the pipeline turn at a certain angle, and the nominal pressure is 1-1.6Mpa.

The common angles are 45 ° and 90 ° 180 °. In addition, there are 60 ° and other abnormal angle elbows required by the project.

The materials of elbows include cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, nonferrous metals and plastics.

The common connection methods with pipes include direct welding, flange connection, hot melt connection, electric melt connection, threaded connection and socket connection.

Use of stainless steel elbow

The stainless steel elbow for general purpose is rolled by ordinary carbon structural steel, low alloy structural steel or alloy structural steel, with a large output, and is mainly used as the pipe or structural part for transporting fluid.

Precautions for use of stainless steel elbow

1.During installation, the stainless steel elbow can be directly installed on the pipe according to the connection mode, or can be installed according to the use position. Under normal circumstances, it can be installed anywhere in the pipeline, but it needs to be sealed to prevent flushing leakage and affect the normal operation of the pipeline.

2.When ball valve, globe valve and gate valve with stainless steel elbow are used, they can only be fully opened or closed. They are not allowed to be used for flow regulation to avoid sealing.

3.For long-term storage of stainless steel elbow, regular inspection shall be carried out. Exposed machined surfaces shall be kept clean, dirt shall be removed and neatly stored in a ventilated and dry place indoors. It is strictly forbidden to stack and store in the open. Always keep the stainless steel elbow dry and ventilated, keep the retainer clean and tidy, and store it according to the accurate storage method.

Application field of stainless steel elbow

Stainless steel elbow is widely used in petroleum, chemical industry, nuclear power plant, food manufacturing, construction, shipbuilding, paper making, medicine and other industries. It has different uses in different industries and shows its use value in various industries.

Difference between stainless steel elbow and carbon steel elbow

The main difference between stainless steel elbow and carbon steel elbow is the material. Its chemical composition will keep the elbow surface from rust and corrosion for a long time. It can be converted into:

1. Production methods: pushing, pressing, forging, casting, etc.

2. Manufacturing standards: national standard, ship standard, electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

Pressure Rating

Sch5s、Sch10s、Sch10、Sch20、Sch30、Sch40s、STD、Sch40、Sch60、Sch80s、XS; Sch80、SCH100、Sch120、Sch140、Sch160、XXS;

The most commonly used are STD and XS.

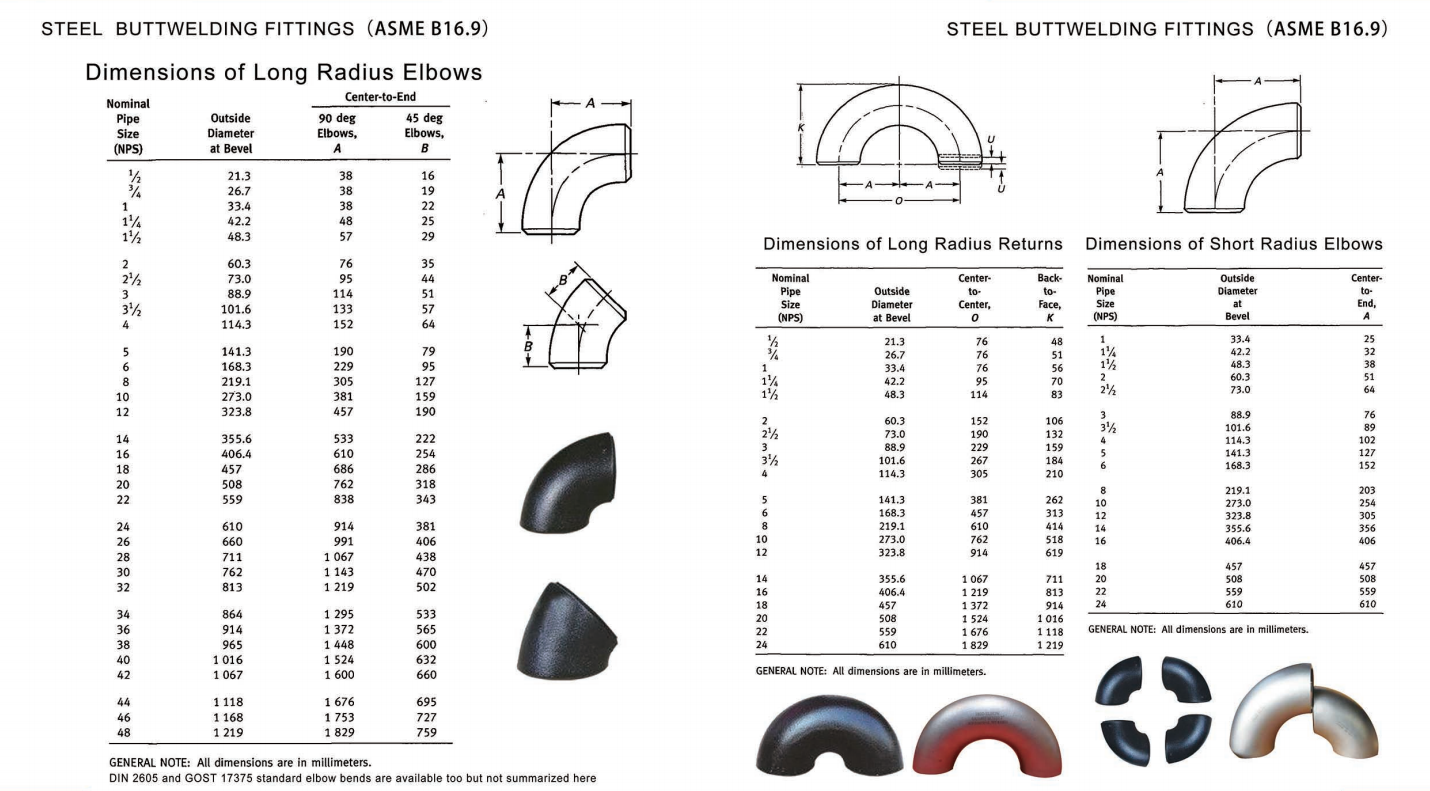

Dimensional Data

Matters Needing Attention

1.During installation, the stainless steel elbow can be directly installed on the pipeline according to the connection mode and installed according to the use position. Generally, it can be installed on any position of the pipeline, but it needs sealing to prevent leakage and affect the normal operation of the pipeline.

2. When using stainless steel elbow ball valves, globe valves and gate valves, they are only used for full opening or full closing. They are not allowed to be used for flow adjustment to avoid sealing.

3.The stainless steel elbow that has been stored for a long time shall be inspected on schedule. The exposed processing surface must always be kept clean, and the dirt shall be removed. It shall be stored neatly in a ventilated and dry place indoors. Stacking or outdoor storage is strictly prohibited. Always keep the stainless steel elbow dry and ventilated, keep the retainer clean and tidy, and store it according to the accurate storage method.

Tips: There are many things to pay attention to when stainless steel elbows are used. Users should use them in a certain way, and use and maintain them in an accurate and reasonable way.

1.Shrink bag–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

One of our storage

Loading

Packing & Shipment

1.Professional manufactory.

2.Trial orders are acceptable.

3.Flexible and convenient logistic service.

4.Competitive price.

5.100% testing,ensuring the mechanical properties

6.Professional testing.

1.We can guarantee the best material according to related quotation.

2.Testing is performed on each fitting before delivery.

3.All packages are adapt for shipment .

4. Material chemical composition is conformed with international standard and environment standard.

A) How can I get more details about your products?

You can send an email to our email address. We will provide catalogue and pictures of our products for your reference.We can also supply pipe fittings, bolt and nut, gaskets etc. We aim to be your piping system solution provider.

B) How can I get some samples?

If you need, we will offer you samples for free, but new customers are expected to pay express charge.

C) Do you provide customized parts?

Yes, you can give us drawings and we will manufacture accordingly.

D) To which country have you supplied your products?

We have supplied to Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine etc. (Figures here only include our customers in latest 5 years.).

E) I can’t see the goods or touch the goods, how can I deal with the risk involved?

Our quality management system conforms to the requirement of ISO 9001:2015 verified by DNV. We are absolutely worth your trust. We can accept trial order to enhance mutual trust.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top